Order Monitoring

Order Monitoring

To be leader in manufacturing of Investment casting products in India by an innovative, entrepreneurial and empowered team constantly creating value and technologies.

To deliver high-quality investment casting products through innovation, advanced technology, and a skilled, empowered team. We strive to exceed customer expectations, drive sustainable growth, and continuously enhance our manufacturing excellence.

Nivic Technocast's 2,600 sq. meter plant features a 26,000 sq. ft. production area with modern machinery. With a 100 MT/month capacity, we currently utilize 35 MT. We offer in-house 3D modeling, 2D CAD drawings, and work with various 3D file formats. Our advanced tool-making facility includes VMC, milling, EDM, and drill machines, ensuring precise product design.

Our Quality control department is equipped with the following instruments.

Company Standards

All the instruments & equipments are regularly been calibrated as per the standards of quality system of the company.

We are using the Spectrometer Spectro MAXx (made in Germany), which is well calibrated with setting-up samples and certified reference materials.

Our spectrometer has the capability to analyze thirty-two elements with high accuracy.

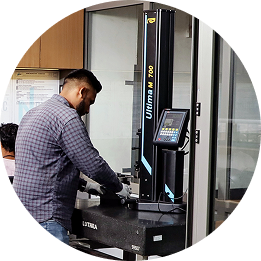

Tensile testing is performed using a well-calibrated Universal Testing Machine with a 10-ton capacity, equipped with a Computerized Extensometer System to calculate Yield Stress (0.2%) and Proof Stress (1%).

Hardness testing in HRC and HRB is conducted using a Brinell Hardness Testing Machine, which is NABL calibrated.

Micro analysis is conducted using an Olympus Microscope (made in Japan) with an attached digital camera, offering up to 1000X magnification and an Automatic Computerized Micro Characterization Software.

Our time-tested process controls are supported by customized foundry software, enabling us to cast even the most complex shapes in almost any air-melt alloy.

We conduct metallurgical and ceramic testing, including radiography analysis using IR-192 and Co-60 isotopes, through accredited external contract laboratories. We also have formal consent from these laboratories for such analyses.

We are proud to have a presence in these countries and are deeply grateful to our loyal clients for their continued support!

Have a project in mind? Drop your email, and we'll reach out.